In power electronics, a small but powerful component plays a key role in enabling the control and conversion of electrical energy. The IGBT module is a technological marvel that is at the heart of countless devices and systems we encounter every day. This article delves into the world of IGBT modules, revealing their meaning, structure and applications. Whether you're an engineer seeking to deepen your understanding, or just curious about the inner workings of modern technology, join us as we demystify the IGBT module and its impact on the electrified world.

Content structure

Problems solved by IGBT modules

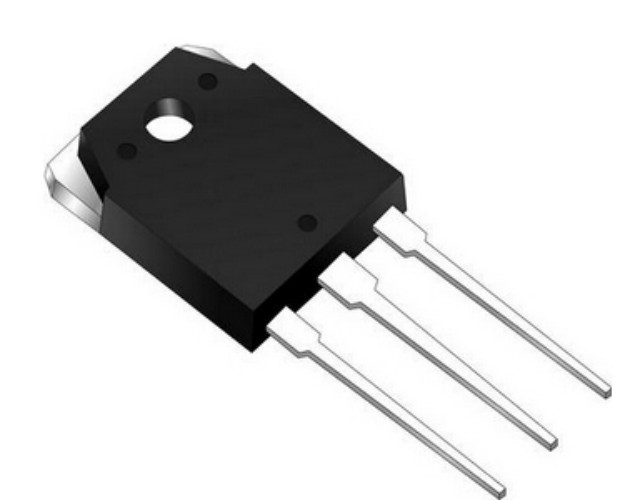

What is IGBT?

IGBT is a semiconductor device that combines the characteristics of MOSFET and BJT. It has the advantages of low on-resistance and high switching speed, and also has the characteristics of high voltage tolerance and strong current carrying capacity of BJT devices. Therefore, IGBT devices are widely used in high-power, high-frequency power electronic equipment.

igbt

IGBT Module Meaning

An IGBT module refers to a packaged semiconductor device that integrates one or more IGBTs (Insulated Gate Bipolar Transistor chips) and related components such as diodes, gate drivers, and protection functions into a single module. The purpose of an IGBT module is to provide a compact and manageable package containing all the necessary elements to control high power currents. IGBT modules are commonly used in power electronics applications that require high voltage and current switching, such as motor drives, inverters, power supplies, etc.

igbt module

Problems solved by IGBT Modules

IGBT (Insulated Gate Bipolar Transistor) modules solve a fundamental challenge in power electronics: efficiently controlling and switching high power loads while minimizing losses and heat generation. It bridges the gap between the voltage control of MOSFETs and the current-carrying capability of bipolar transistors, combining the best of both worlds to enable high-voltage and high-current applications with improved efficiency and switching speed.

If you are interested in the internal structure and working principle of IGBT module, you can read here.

Before the IGBT module

Before the widespread adoption of IGBT modules, power electronics faced limitations and inefficiencies, especially in high power applications. The main semiconductor devices used are bipolar transistors and thyristors (SCRs), each with their own disadvantages:

Bipolar Transistors: Bipolar transistors have excellent current carrying capacity, but due to their inherent characteristics, they switch slowly and have relatively high power losses during switching. This limits their use in high frequency applications and results in significant heat dissipation.

Thyristors (SCR): Thyristors are very robust and can handle high voltage and current levels, but they can only be turned on and not turned off until the current through them drops to zero. This characteristic, known as "latch-up," makes them unsuitable for applications that require precise control and fast switching.

The limitations of these devices limit the efficiency, speed, and complexity of power electronic systems. The system is larger, less efficient, and requires additional components for on-off control.

IGBT module advantages

IGBT modules combine the advantages of MOSFETs and bipolar transistors to become a revolutionary solution to these challenges. It has the following main advantages:

High Voltage and Current Handling: One of the defining advantages of IGBT modules is their exceptional ability to handle high voltage and current levels. This makes them ideal for applications requiring large amounts of power, such as industrial machinery, electric vehicles and renewable energy systems. IGBT modules efficiently manage the flow of large amounts of power without compromising performance.

Fast switching speed: The fast switching speed of IGBT modules makes them stand out in the field of power electronics. Their ability to rapidly transition between on and off states facilitates efficient power conversion and control. This feature is critical to minimize power loss during switching, thereby increasing energy efficiency in a variety of applications.

Reliability: IGBT modules are designed for reliability with built-in protection features and a rugged design. These modules typically include overcurrent protection, overvoltage protection, and temperature monitoring mechanisms. These safeguards not only ensure optimal performance, but also protect the modules from potential damage, extending the overall life of the system.

Temperature tolerance: One of the notable features of IGBT modules is their ability to operate efficiently over a wide range of temperature conditions. Whether in extreme heat or cold, the IGBT modules maintain their performance and reliability. This temperature resistance makes it invaluable in applications where environmental conditions are varied and dynamic.

MOSFET-like gate control: Like MOSFETs, IGBTs can be controlled with low power levels and voltages, making them compatible with modern digital control circuits.

Ease of driving: Compared to thyristors, IGBTs require a simpler gate drive circuit, resulting in more precise control and faster switching.

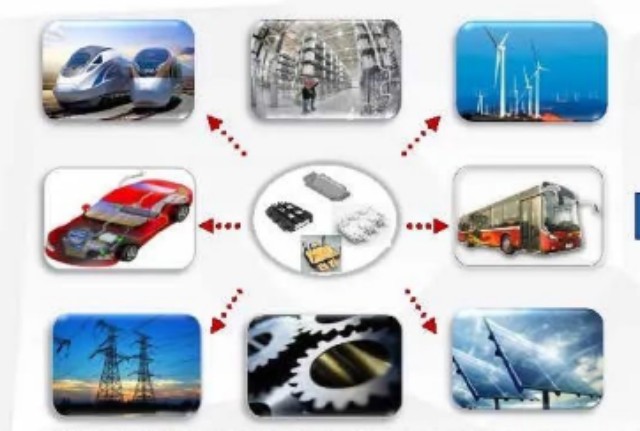

Application of IGBT module

The advantages of IGBT modules open the door to numerous applications in various industries:

Industrial automation: IGBT modules use their power handling and switching functions to drive motor control systems, conveyors, and robots in industrial environments.

Renewable energy systems: IGBT modules are at the heart of solar inverters and wind turbine controls, where their efficiency and reliability contribute to optimal energy conversion.

Transportation: Electric vehicles and trains benefit from IGBT modules due to their high power handling capabilities for efficient energy conversion and propulsion.

igbt module application

In conclusion

In a world where efficient power control and energy conversion is critical, IGBT modules are the cornerstone of innovation. The fusion of its power transistor functionality and smart gate drive circuitry enables seamless transitions between switching states, supporting a wide range of devices such as electric vehicles, industrial motor drives, renewable energy systems, and more. As technology advances, IGBT modules continue to evolve, pushing the limits of power electronics. With their impressive power handling capabilities and vital role in modern engineering, IGBT modules undoubtedly remain the driving force in the electrified future we are building.

Need Help?

Need Help?